Rotomolding Resilience: Creating Strong and Impact-Resistant Plastics

Rotomolding, also known as rotational molding, is really a producing method that entails developing plastic-type material merchandise by making use of high temperature and rotational motion. This procedure is incredibly flexible and may be used to create an array of merchandise, from huge storage containers to children’s Rotational Molding toys and games. In the following paragraphs, we’ll consider a close look at the procedure of rotomolding, the benefits it provides, and some of the key factors to bear in mind when using this technique.

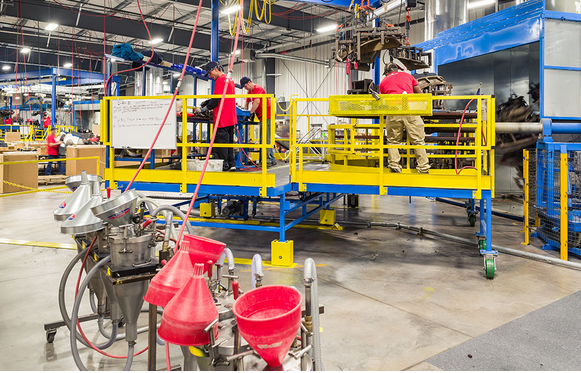

The Rotomolding Approach

Rotomolding can be a three-period procedure that requires reloading a thermoplastic resin in a mildew, melting the resin under substantial temps, and turning the mold around two perpendicular axes. As the resin melts, it coats the interior top of the mold, taking up its condition. When the fungus is sufficiently cooled, the finished product is removed and prepared to be used.

One of many crucial benefits associated with rotomolding is the fact it can be used to produce large and sophisticated styles without having seams or important joints. Because of this the done item is often more robust and a lot more long lasting than items created through other developing approaches. Additionally, rotomolding can be used with a variety of resources, such as high-solidity polyethylene, polyurethane, and Pvc material.

Style Concerns

When making products for rotomolding, there are a few crucial factors to keep in mind. To start with, it is crucial that you layout with the manufacturing method in your mind. This simply means considering factors like the fungus sizing, walls density, and fabric kind. Moreover, it is essential to take into account the concluded product’s intended use as well as the circumstances it will be subjected to. This will help to ensure that this product is just as strong and durable as possible.

Great things about Rotomolding

Rotomolding delivers a wide range of advantages over other developing operations, including:

– Reduce tooling charges: Due to the fact rotomolding employs basic molds and fails to call for the usage of high-priced tooling gear, it is often less costly than other developing tactics.

– Increased design and style flexibility: Rotomolding provides for increased versatility in layout and the development of intricate styles.

– Durable items: Items developed through rotomolding are often more durable and resistant against problems than others created through other manufacturing operations.

– A more secure approach: Contrary to other manufacturing operations designed to use heating and pressure to make items, rotomolding does not make any harmful by-products or demand the usage of harmful substances.

Simply speaking:

Rotomolding is actually a valuable manufacturing procedure that has been popular to generate an array of plastic-type products. This process provides a number of significant benefits over other production tactics, which include lower tooling expenses, increased design and style mobility, and a lot more tough items. Design and style factors are very important and should be considered when creating goods for rotomolding, nevertheless the finished products’ durability and strength make it the valuable choice for several software. If you are searching for learning more about the rotomolding method, don’t wait to get in touch with among the many experienced rotomolding manufacturers that can assist you in the creation of your plastic product.